Overview | Processes | Technologies | Sectors | Other Services | Contact

Would you like to discuss a project?

Telephone: +44 (0) 121 556 4451

Email: design@newbyfoundries.co.uk

Specialists in the development & production of rapid prototype sand castings

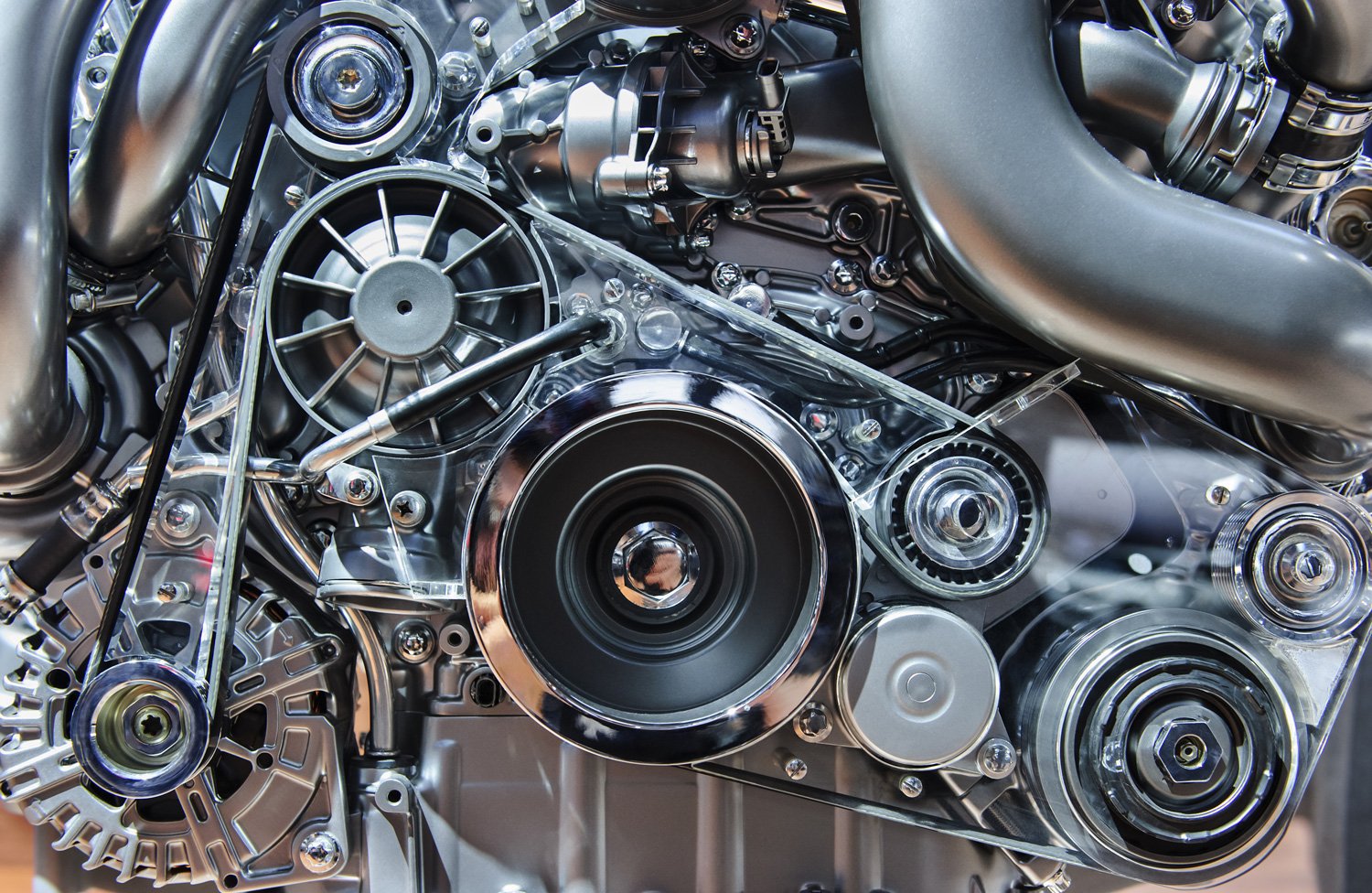

Newby Foundries RapidCast manufacture and supply rapid prototype castings in a variety of sizes, materials, finishes and quantities. We utilise the facilities of the Newby Foundries Group, along with our own range of 3D printing processes, to provide customers with the most suitable casting solution for many applications. Depending on customer requirements our prototype castings are highly representative of, or identical to production parts.

1,260 Litre 3D Sand Printer

7 Laser 3D Scanner

SolidWorks CAD Software

MagmaSoft Casting Simulation Software

Newby RapidCast provides a rapid prototype casting service for:

1 offs

Limited runs

Development from prototype to production

Primarily we produce castings in conjunction with the Newby Foundries Group:

Newby Foundries Iron – Iron sand cast prototypes

Newby Foundries Steel – Steel sand cast prototypes

Newby Foundries Light Alloys – Zinc and aluminium sand and gravity die cast prototypes

Newby Foundries Precision Machining – Prototype machining

Collaboration is Key

We work with the Newby Foundries Group to provide a comprehensive service.

Rapid Lead Times

Several 3D printing options are available for super-fast turnarounds.

Fully Representative Prototypes

We produce prototypes which are identical to production castings.

Processes

For other non-ferrous sand castings we can provide select partner foundries with prototype moulds or tooling and supply customers with prototype castings in materials that would not otherwise be achievable. For lost wax prototypes please visit Newby Foundries Investment Casting. We also work with select sub-contact suppliers for services. Various finishing options are available and if needed castings can be supplied fully machined.

Find out more about the processes we offer below.

3D Sand Printing

Fast turnaround

Prototype & production quantities

No tooling required

Geometric freedom

Can be combined with conventional moulding processes

Specification

Highly compatible: Furan binder system

Large bed size: 1,800 x 1,000 x 700mm,

Fine layer thickness: 280 - 500μm

Fast build speed: 60,000 - 85,000 cm3/h

High tolerance: CT9 achievable

3D Printed Tooling / Airset Moulding

Markforged X7

Carbon fibre filled nylon

Continuous fibre reinforcement

Short lead times

Low volume batches

Basic non-cored castings

Other uses

Functional prototypes

Fixtures

Lost wax tooling

Specification

Large bed size: 330 x 270 x 200mm

Fine layer thickness: 50 - 200μm

Resin Tooling / Airset & Cold-Box Moulding

Low density grade 750 resin board

Reduced lead time

Lower cost

Production Tooling

All casting processes from the Newby Foundries Group are available for prototypes

Hybrid Moulding

Often the optimal casting solution is a combination of processes

Technologies

As standard we offer in-house design for manufacture services using cutting edge software such as SolidWorks for CAD and MagmaSoft for mould flow analysis & solidification simulation. Other technology services include 3D laser scanning for casting & tooling validation and reverse engineering.

3D Laser Scanner

Reverse engineering

Casting validation

Tooling Validation

GOM Suite software

Deviation plot colour map reports

Handheld system

Easy to use and portable

Fast operation

30 blue laser system

Scanning rate: 2,020,000 measurements

High accuracy with variable resolution

Volumetric accuracy: 0.02mm

Suitable for large components

Scanning area: 410 x 400mm

Integrated photogrammetry for larger parts

Deep hole capture

MagmaSoft Casting Optimisation Software

Mould flow analysis

Flow rate

Filling temperature

Solidification simulation

Hot spot prediction

Porosity prediction

Casting yield

Core gas prediction

Virtual optimisation of casting processes

SolidWorks

CAD engineering software

Design for manufacture

Thickness analysis

Draft analysis

Sectors

Newby foundries Rapidcast operate in the following industries:

Our broad customer base spans many sectors and industries including automotive, electric vehicle, defence, oil & gas, rail, construction and general engineering OEMs. Examples of castings we produce include turbine housings, bearing housings, battery enclosures, brackets, hydraulic valves, manifolds, housings.

Other Services

Discover the services Newby Foundries RapidCast can also assist with:

QUALITY

Material testing laboratory

Dimensional analysis reports

MPI, DPI & X-ray

Pressure testing

Ultrasonic testing

FINISHING

Heat treatment

Pickling & passivating

Plating

Painting

Anodising

Galvanising

Divisions

Explore the Newby Foundries Group

The Newby Foundries Group produce high quality castings in a variety of materials, sizes & finishes across our 4 sites. Our range of casting processes, combined with our ability to develop castings from prototype through to production means we can provide customers with an optimal casting solution for many applications.

We produce rapid prototype castings using the latest technologies such as 3D sand printing, simulation software and 3D scanning

Would you like to discuss a project?